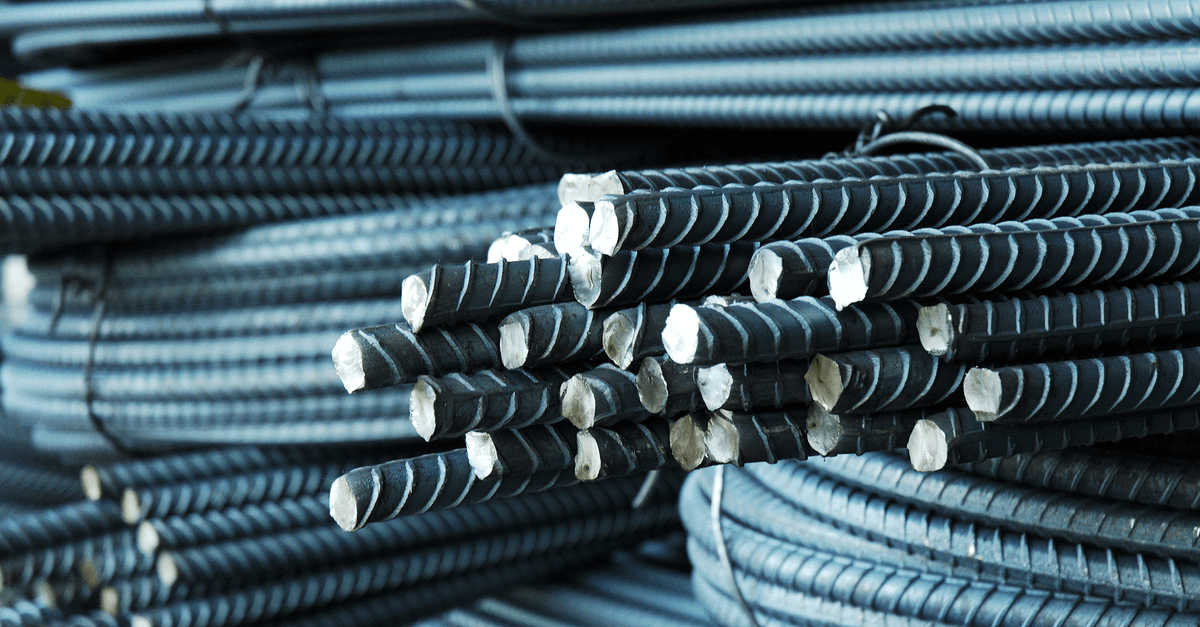

TMT Bars

-

TMT bars, also known as Thermo-Mechanically Treated bars, are renowned for their high

strength and durability. They feature a tough outer core and a softer inner core,

achieved

through a meticulous manufacturing process.

-

Initially, steel wires undergo rolling in a mill stand. Subsequently, the rolled wires

pass

through a Tempcore water cooling system, where water pressure is optimized. This process

involves sudden quenching and significant temperature changes, enhancing the outer

layer's

toughness and durability.

-

Following this, TMT bars undergo atmospheric cooling to balance the temperature

disparity

between the inner and outer layers. This meticulous process ensures that TMT bars

exhibit

superior strength and resilience, making them ideal for various construction

applications.

Application

TMT bars have emerged as the preferred choice in construction, finding extensive

application in various projects, including:

-

Residential construction

-

High-rise residential buildings

-

Dams

-

Large-scale structures such as malls, schools, airports, and hospitals

-

Underground constructions

-

Marine structures

Choosing TMT bars ensures the construction of long-lasting, cost-effective, and durable

structures. However, it's essential to procure from a reputable manufacturer to

guarantee

the authenticity and quality of the product.